Media Indonesia - In a corner of Fisheries and Marine Sciences Department of the Universitas Padjadjaran field laboratory in Jatinangor, Sumedang lies 15 plastic buckets neatly arranged in a row. They contain a green liquid. The liquid in a glance reminds us to an abandoned pond covered with aquatic weeds. In fact they look similar.

The Dean of the Fisheries and Martime Sciences Department, Dr. Iskandar Muchtar, explained to Media Indonesia, on Wednesday (4/20) that the plants covering the plastic buckets are Lemna Sp. (duckweed) which are often considered to be undesirable aquatic plants. However, the field laboratory, deliberately cultivates the plants. “This plant (duckweed) are high in protein, the protein content ranges between 20-30%, depending on the types and sunlight exposure. Therefore thes plants are suitable both for herbivore and omnivore fishes,” descibes Iskandar which then picks up a duckweed and put it into a pond where gourami fishes are raised.

Shortly thereafter, tens of fish emerged into the surface. They splashed the water excitedly as they compete with each other to consume the plants which are also known as duckweed. The research to utilise Lemna or duckweed as the fish feed has been started since 1970s. However, the utilisation in a vast scale has not really been seriously considered due to limited supply of the plants. Iskandar explains, even though the plants are considered as undesirable organism, Lemna does require a serious attention to enable a proper growth. In addition to requiring sufficient sunlight exposures, Lemna also requires a conditioner.

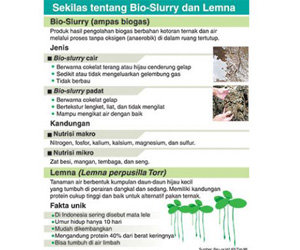

In the case of the Fisheries and Maritime Sciences Department of the University of Padjadjaran, high level of Lemna growth has been achieved through the use of bio-slurry. Bio-slurry is an organic slurry produced by fermented undigested slurry. To secure the supply of bio-slurry, Iskandar has established collaboration with Rumah Energi, a foundation which promotes the use of biogas as the source of local energy. Based on the research performed by the students at the Fisheries and Maritime Sciences of the University of Padjadjaran, it is known that bio-slurry addition will enhance twice as much growth level of Lemna plants. These results were found out after adding bio-slurry to a 1-kg of Lemna followed by 16 hours of monitoring. Nonetheless, Iskandar has not identified the most suitable volume for adding this liquid bio-slurry.

So far, the research has used a 2.5 mililiter of bio-slurry mixture for each liter of water. He hopes that the results of the research on bio-slurry dosage, types of fish, as well as period of feed supply for the best growth level of fish will be obtained within the two month periods.

From Soil Conditioner to Pesticide

Organic Fertilizer Officer of Rumah Energi, Yudha Hartanto, presented that in addition to the liquid fom, bio-slurry is also utilised in its solid form. Average nitrogen content of liquid bio-slurry is known to be higher.

Not only for the plant growth, bio-slurry has also been experimented as soil conditioner, source of food for earthworm, and as organic pesticide and fungicide. Soils treated with bio-slurry will be more crumbly as well as easily retain the nutrition and water. These slurry will also be able to improve the population and activities of earth organisms.

On the other side, the long period of utilisation often time is difficult due to unstable bio-slurry quality. Due to the similar reason, most bio-slurry have been left as they are.

“Survey results of biogas users suggested that 20% of them simply discharged the bio-slurry. Firstly, they have no knowledge on its benefits; secondly, there are not enough time to take care of it hence they simply discharge it as a waste. In terms of the quality, the best quality of bio-slurry is produced through the bioconversion of poultry dropping,” Yudha said.

During biogas production process, bio-slurry normally starts to form between day 50 to day 60 after the cattle manure were fed to the reactor. Even though it is frequently referred to as waste products, bio-slurry retains a significantly high nutrient content while remaining at the safe level. Nevertheless, in case on the need to reutilse the bio-slurry, then the process should be performed as soon as possible to avoid the loss of nutrient contents due to the continuous anaerobic process of the powder.

Source: http://www.mediaindonesia.com/news/read/44082/inovasi-pakan-dari-unpad/2016-05-07